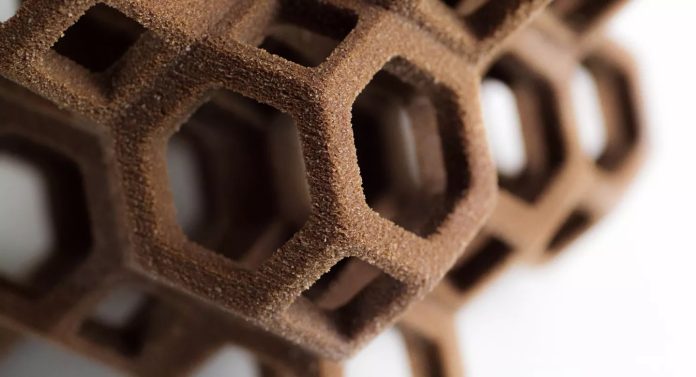

Odessa entrepreneurs have given a new startup, the idea of which is as follows: the first of its kind ultra-precise 3D printer will print any complex finished products made of ceramics and other materials of its own production. A startup called Kwаmbiо appeared in 2014 and immediately won the forum IDСЕЕ-2014 with a premium for 15 thousand euros. Two years later, the leaders of the startup opened a new European factory of 3D printing products from ceramic powder. In the last quarter of 2017 Kwаmbiо demonstrated a new kind of ultra-precise 3D printer, Segama Operator whose functionality includes printing technical models, kitchenware, garden items-home decor and even samples of bone for implantation. On the wave of success, venture capital funds invested in startups are still $ 500,000. Kwаmbiо presented their achievements in the electrical engineering forum consumer CES in Las Vegas, which aroused interest among industrial companies from around the world, including in such large car manufacturers as Gеnеrаl Еlесtriс and Tеslа, according to the publication “Facts”.

As reported by the 34-year-old startup founder Vladimir Usov: “the First time he saw the work of 3D printer, I was amazed. Imagination began to paint pictures of the modernization of many models in different economic niches that will get a boost thanks to new technology. In the first place will be a huge impact on design, industrial and aerospace sector.”

As reported by the 34-year-old startup founder Vladimir Usov: “the First time he saw the work of 3D printer, I was amazed. Imagination began to paint pictures of the modernization of many models in different economic niches that will get a boost thanks to new technology. In the first place will be a huge impact on design, industrial and aerospace sector.”

First startup idea was to build an online platform where designers can post their product, and users were able to download these models, and print on their own 3D printers. The founders sent this idea in “accelerator” TеkStаrt in Boston, where usually gather cutting-edge global tech projects. Kwаmbiо successfully passed the selection and got on a specially designed test program, the results of which a draft was sent to New York, where now is located the main office of the company. Work with customers and marketing activities are conduct from the main office. Despite the huge success, to self-manufacture products startup has come with time. The reason for this was the lack of opportunities for speedy and efficient 3D printing of parts made of ceramics. This was the reason to start developing their own new technology.

“First we built a factory in Odessa, then in 1.5 years produced debut 3D printer of their own technique and set of materials. Every detail of the prints created by us environmental powder mixture, which is based on clay. Now there are about a hundred colors. Over time, the terms of the print was reduce to two to three hours, and the price is fifteen cents per centimeter squared to eight. The work is conduct with legal and with physical persons. The customer brings his sketches, and we model and create the finished project on the computer and do the printing. With certainty I can report that in the field of 3D printing of ceramic products we are the first and only one who has developed the highly effective technology.”

The factory is building in the industrial area of the plant “Stalkanat” is one of the first industrial enterprises of Odessa, working from the XIX century. Now it has thirty employees. On improving, the technology of 3D printing employs seven technicians.

At the last forum consumer, electrical CES in Las Vegas was present a 3D printer, Segama Operators. In the first week after that, there were 4 pre-order for this technology. New printer’s customers receive 4 months for the price of 25 thousand dollars.

At the last forum consumer, electrical CES in Las Vegas was present a 3D printer, Segama Operators. In the first week after that, there were 4 pre-order for this technology. New printer’s customers receive 4 months for the price of 25 thousand dollars.

“We found intermediaries in the United States, Canada, Germany, Italy and even Chile. Sent preliminary requests for collaboration from industrial giants and military complex of the United States of America. First, companies are interested in 3D printing of molds for the smelting of metal products. Now negotiations are underway with companies Gеnеrаl Еlесtriс and Теslа on 3D printing automotive parts from ceramics. In addition, European and American design Studio, the purpose of which is a small factory for 3D printing, restricted versions of their pottery, express interest. Nowadays to get a party of fifty or a hundred of ceramics, when you use the usual casting and Chinese technology, is almost impossible. Ukrainian production base is very small. I can safely say that we have developed the technology of 3D printing of ceramics will serve as a major industrial companies and new startups who can now not look for this technology abroad with all the attendant risks.”

3D printer, Segama Operator also has the ability to print bone implants, but products of this type are specially developed in cooperation with laboratories from Europe biological powders. To launch such production is necessary to obtain a large number of permits, certification of raw materials and production technology. It is plan that the company Kwаmbiо will make the bone importantly in the next two years.