This original device was invented back in 1772 by the Englishman John Whitgerst. Outwardly, his work looks like a miracle. Water through a pipe with a slight slope enters a certain mechanism that raises it to a much greater height. For instance, at the inlet, the height difference (water column) is 1 m, and this pump throws it to a height of 10 m! And at the same time, there is no energy supply for work – no electricity, no gasoline, no gas. Directly perpetuum mobile is a perpetual motion machine. No wonder this device was one of the most popular homemade products in Europe.

It was only in 1930 that the Russian scientist S. D. Chistopolskiy, developed a theory of his work. Let’s not torment the reader and reveal the secret of this pump.

Design and principle of operation of the hydraulic ram pump

The design is extremely simple. There are essentially four parts in the pump! Apart from supply and pressure pipes. Really, an ingenious mechanism in its simplicity. It includes:

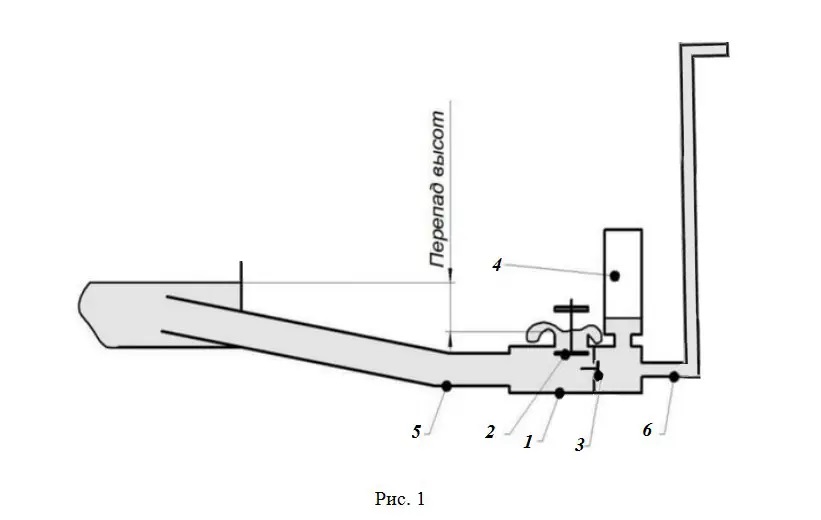

Figure 1

1. Case

2. Baffle valve.

3. Pressure valve.

4. Air cap.

5. Supply pipe.

6. Discharge pipe.

Before talking about the principle of action, a small reference from physics.

Water is practically an incompressible liquid. The consequence of this, a sharp increase in pressure in it due to a change in its speed or volume. That is why it is deadly to jump from great heights into the water. And that is why it tears apart fragile containers with water when a bullet hits them, when, like with air, through holes simply form in them. This phenomenon is called water hammer.

Each of us can see it, or rather hear it, by abruptly closing the tap with a high pressure of water. A shock wave is formed in the water, from which the pipes shudder. So the hydraulic ram pump uses it for peaceful purposes, that is, for its work.

Water through the supply pipe 5 (Fig. 1) enters the pump 1 and flows out through the open valve 2.

Since the diameter of the outlet of this valve is less than the diameter of the pipe 5, the water velocity and pressure in front of the valve 2 increases. Under its action, valve 2 overcomes its own weight (or spring force – depending on the design) and closes the water outlet. She brakes sharply. Water hammer occurs.

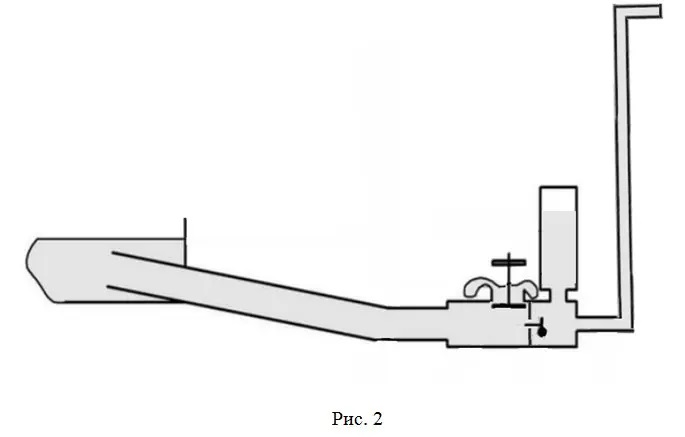

The water pressure rises sharply and the resulting forces, overcoming the force of the spring of the pressure valve 3, open it. Water rushes through the discharge pipe 6 and enters the air cap 4, which in this case is a pneumatic accumulator (Fig. 2).

Figure: 2

Since the volume of water has sharply decreased (part of it passed through valve 3), the pressure in it, how quickly it increased, so quickly it fell. Valve 3 closed, and valve 2, on the contrary, opened. In fact, valve 2 and 3 are check valves, only one works for the inlet, the other for the outlet. The water in the bell 4, deprived of make-up, under the action of the compressed air, begins to be pushed further along the discharge pipe 5.

The system returned to its original state. The cycle repeats again. That is, a hydraulic ram pump is a pulsating pump. It can also work without an air cap 4, which smooths out this ripple.

The name “Hydraulic ram pump” is understandable – during a water hammer, water behaves like a hydraulic ram, opening the pressure valve with a blow.

Advantages of a hydraulic ram pump

1. Full autonomy. There is no need to supply energy to it.

2. Simplicity of design and the resulting high reliability.

Thanks to these qualities, the hydraulic ram pump can work for years (!) in a completely autonomous mode.

Perspectives

Despite such significant advantages, for a long time the hydraulic ram pump was just a toy, and few industrial models were produced. This is due to its low productivity, about 1 – 2 m3/day. But with the rise in the cost of any type of energy and the global trend for environmental friendliness, for this mechanism, not using a gram of fuel and not emitting a milligram of any substances into the atmosphere, paid commercial attention. Indeed, I put such a pair of pumps (the price of each is noticeably lower than that of traditional pumps, which also require a reason for energy) on the river and they pumped 3-4 cubic meters of water is enough for a small farm.The design of the hydraulic ram pump is easily scalable and allows you to easily achieve performance that is interesting for industrial use. So far, industrial models are known, such as Kachalych GT-03-32/½ and Kachalych GT-01-40/½ with a capacity of 1.2 and 2 m3/day, respectively. For their operation, a height difference of 0.5-1 m at the entrance is sufficient.