Scientists have created an innovative installation that has performance indicators 2 times higher than that of a conventional refrigerator. At the same time, the device does not require refrigerant.

The principle of operation of the installation is based on the transfer of heat through the use of metal “muscles”. Artificial muscle tissue is made of titanium-nickel. It is worth noting that the “muscles” have shape memory.

In the process of expansion, these muscle fibers absorb thermal energy, and when they return to the initial state, they release energy. The creators of the technology note the temperature difference in this process by 20 degrees Celsius.

A group of scientists notes that the strands of nitinol in tension, when unloading at room temperature, become colder by 20 degrees.

Such indicators are minimal, because obtained from the prototype in the laboratory. According to the inventors of the new technology, their development is capable of more. This system is able not only to cool effectively, but also to heat it. The efficiency of the device is 2-3 times higher than that of conventional heating or cooling devices. It should be noted that this technology is completely environmentally friendly and environmentally friendly.

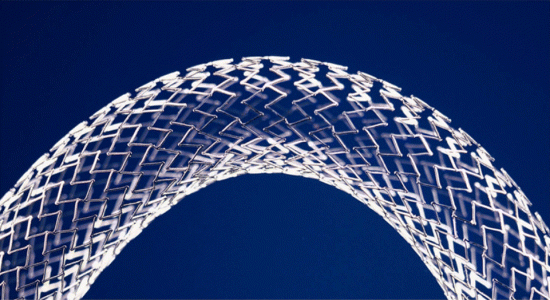

The device has the form of a cylinder that rotates continuously. On the walls of the cylinder are wound threads of nitinol. During the accelerated rotation of the thread on one side of the installation stretch and absorb thermal energy from the air. When they move to the other side, a compression occurs and the nitinol bundles give off thermal energy to the outside.

For full operation, the installation should be equipped with special boxes in which the fans will be installed. The blades will drive the air in the system, thereby creating a hybrid source of heating and cooling.

As part of the Ferroic Cooling program, invested by DFG, this technology has been studied for several years. As a result of such serious scientific work, it was possible to determine the specific number of nitinol filaments, the installation rotational speed and the load level on the nitinol bundles, at which the efficiency of the device will be maximum.

With increasing area of the rotating cylinder, the process of heat transfer is accelerated. Nitinol threads began to be bundled for rapid cooling. During the testing process, a television camera was used. She allowed to conduct an accurate analysis of the stages of raising and lowering the temperature.

The main secret of successful device operation is the most accurate calculation of parameters. The capacity of the installation is 30 times more than nitinol threads require for compression or expansion.

The study of the parameters of the system allowed the developers to customize its work in the smallest details for specific needs. The addition of the installation was a special software developed specifically for it. Now the setting of the heating and cooling parameters is done through the computer. At the end of the software development and modeling phase, the system can be launched.

The inventors note that the new device is 2 times more efficient than the heat pump and 3 times the refrigerator. The system does not require the inclusion of toxic substances in it, it does not have heat exchangers and pipes, because the air is cooled directly. Nitinol was not chosen as the main material. This alloy has high fatigue resistance. This allows you to guarantee the full functioning of the system for many years.