The most popular on the market at the moment are steel and aluminum mounts for solar panels. The main reason for choosing such fasteners is durability and the illusion of reliability. If metallic, it will last much longer than any other material, they say. But the reality is a bit different from this perception.

Steel and aluminum mounts of solar panels are exposed to temperature fluctuations and corrosion. They expand under the influence of heat and contract in cold weather. They also increase the chance of lightning to strike solar panels, which is likely to disable the entire battery. Particularly vulnerable metal structures near the sea. The sea breeze greatly accelerates corrosion processes.

Of course, metal mounts can be protected by paint or a special coating, which reduces their heat in the sun and prevents corrosion. They can also be covered with a dielectric material. But this greatly increases the cost of construction.

Polymeric mounts for solar panels

Today, there are plenty of materials that are as strong as steel or aluminum and are extremely durable. These materials are polyamides, poly-carbonates, polypropylene and polyacetal. These materials are not weaker than metals in their properties, but have many times longer life, lower mass and are dielectrics. And composite materials deserve special attention in this segment.

Mounts for solar panels from composite materials

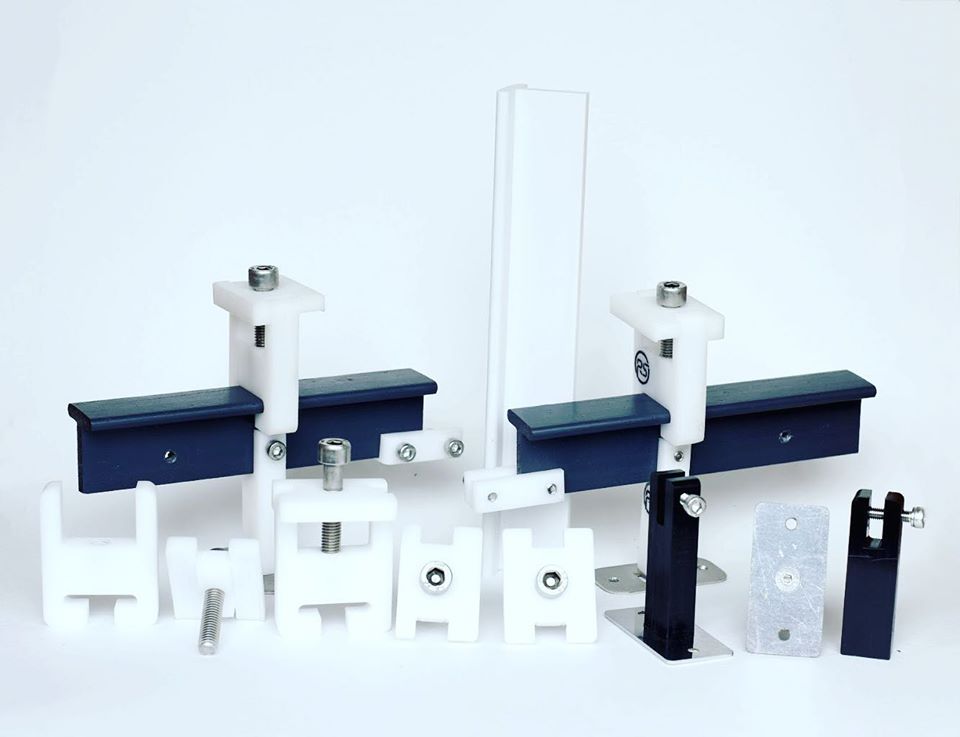

Reliable, durable, lightweight and inexpensive composite fasteners were developed by the Ukrainian company LLC RS-PROJECTS. The fastenings consist of a composite of polyacetal with the addition of sand and aluminum shavings, as well as the addition of secondary raw materials. Such material has high hardness, absolutely not subject to corrosion and influence of temperature differences. It is not in need of dielectric protection. More details at https://rs-project.org

The advantage of RS fasteners is their ease and ease of installation. Drilling is kept to a minimum, as is the use of bolted connections. Such structures do not require welding, like some metal ones. All you need to do is to fix the base on the roof, and then install solar panels on them and hold them in place. This design can be easily expanded or dismantled as needed.

Extremely easy to install

Despite its lightness, the composite material is well protected from any kind of damage. It is difficult to cut with a hand-held tool that protects panels from theft.

What is Composite Profile and Fastening for?

The use of composite polymeric materials is very common and is not limited to solar plants on the roofs of private homes. Profile structures of composite polymer are excellent in the installation of solar plants not land, as well as the installation of sheds over parking lots, the construction of roofs of commercial and residential buildings, the assembly of various sandwich panels, erected arbors and the construction of fast-mounted structures of various purposes.

Summing it up

Composite polyacetal with impurities of sand and aluminum shavings is the material of the future with the following advantages:

- High strength on a level with steel.

- The weight of the profile and fastenings is 2 times less, which significantly speeds up mounting and reduces the cost of both transportation and installation.

- The material is not subject to corrosion, temperature. Is a dielectric.

- Easy to paint.

- The material is suitable for delivery for processing.

- Made in Ukraine.

The availability of such material calls into question the need for heavy and expensive steel or aluminum. After all, there is a material that is ahead of metals in almost all indicators.

RS-mounts for solar panels on the roof.