The number of wind turbines is growing from year to year, but the new development of GE Renewable Energy significantly exceeds its competitors, as it will reduce costs, increase profits and efficiency.

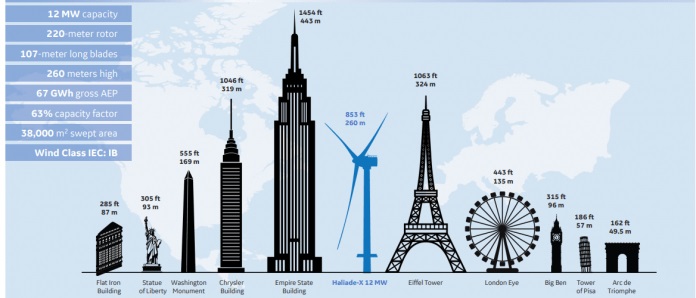

The company will spend $ 400 million on a powerful turbine project that will significantly reduce the cost of obtaining wind power. The diameter of the GE 12 MW turbine will exceed 200 m, and the size of its blades exceeds 100 m. The power factor is also striking – 63%.

The use of a turbine, such as Haliade-X, will allow developers to build units with fewer auxiliary turbines, use fewer cables, reduce construction, maintenance and other costs, and enable faster return on investment.

The company estimates that in 2019 it will have a mock-up for the demonstration, and by 2021 the Haliade-X turbine will be supplied to the US and other countries.

The use of equipment with a capacity of 12 MW will also make wind turbines larger in terms of generating capacities than existing ones, which will require a new approach to financing and their deactivation.

Despite the fact that the wind generator Haliade-X will be well suited for a small wind, its power will allow producing more energy than analogues in similar conditions, increasing profitability and significantly reducing the cost of energy.

The 12 MW turbine will be able to generate more than 60 GW per year, which is 44% more than the annual volume of energy production of the most powerful devices on the market today and twice as much as the GE-Haliade marine turbine of 150-6 MW. The Haliade-X 12 MW will be able to generate enough power to supply 16,000 European homes in the traditional windy weather for the North Sea.

The 12 MW turbine will be able to generate more than 60 GW per year, which is 44% more than the annual volume of energy production of the most powerful devices on the market today and twice as much as the GE-Haliade marine turbine of 150-6 MW. The Haliade-X 12 MW will be able to generate enough power to supply 16,000 European homes in the traditional windy weather for the North Sea.

Haliade-X not only set a benchmark for wind turbines, but also the turbine will significantly increase profits for the company’s customers.

The maintenance and repair costs will also be lower due to “simplified technological and intellectual components”.

The new turbine not only helps developers reduce capital costs: with fewer turbines and foundations for installation, in addition to reducing cycle time and simplified operation, Haliade-X 12 MW will also be able to generate significant cost savings for the project over the life of the “windmill “.

Under the terms of the five-year research and development program, the company will test the next-generation technology for Haliade-X, and the turbine will pass test and demonstration programs at the facility that will accurately reflect the actual operating conditions.

Research activities will include cooling technologies, converters, and conditions for loading mechanical and electrical components, testing the network and checking the design.

Cooperation will help improve technology, which will also help develop a number of supplies to the UK and expand access to demonstration opportunities for innovative small businesses.

John Lavelle, President and CEO of the company, said about the decision to test a new turbine in the UK: “This is an extremely important agreement, as it gives us the opportunity to soon prove the effectiveness of Haliade-X, demonstrating its performance under extreme conditions. Catapult engineers will ensure the independent performance, functionality and endurance of each part in particular and the system in general, including the generator and converter, recreating extreme conditions in a controlled environment. The test bench will improve the understanding of the characteristics of the turbine, identify the problems of production and design in a relatively short period compared to field tests. Ultimately, this will shorten the time to market, increase reliability and reduce associated costs and risks”.