The creators of Paragraf are Cambridge workers. They own the discovery of the method of industrial production of graphene.

At this stage, people from the University of Cambridge create special plates of graphene, the diameter of which does not exceed 20 centimeters. A startup from Paragraf will use them as a component of transistors.

A new method of producing graphene on an industrial scale will make it possible to organize the mass production of high-power processors – their performance will exceed the power of silicon analogues by 10 times. The first batch of electronics with elements of graphene will be released soon.

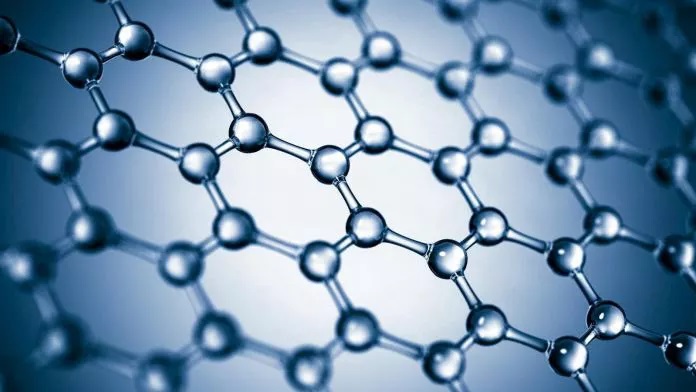

Graphene made a splash in the scientific community when it opened in 2004. The unique features of this material were evaluated in full, and many institutes and laboratories began to work on searching through its most efficient use. The fact is that graphene is 200 times stronger than steel, and indicators of the efficiency of conducting electricity are 10 times higher than that of copper. The electrical conductivity of this innovative material is 250 times higher than that of silicon.

To date, scientists are working on finding budget ways to get graphene. Making it on a production scale is too expensive from a financial point of view. Partly, graphene is used to create batteries, and in the near future it is planned to release aircraft fuselages of this material.

Representatives of the company Paragraf argue that graphene released as part of their startup can be used to produce sensors of the chemical and electrical type. The use of this material in the manufacturing process of sensors will make their sensitivity indicators 30 times higher.

The company Paragraf said that their technology of production of large quantities of graphene – is unique. No one has so far succeeded, without loss of quality, in creating plates of such a diameter. It is worth noting that in the laboratory, members of the group of inventors use graphene flakes, because they are much easier to produce.

The official website of the Paragraf company contains information on the possibility of using graphene plates for the production of touchscreens, photovoltaic modules and sensors. The technology itself is kept secret and is described only by common phrases. According to the creators of the startup, a new method of manufacturing graphene can help translate the great ideas of science fiction into reality.

The secrecy in the wording of the new technology did not prevent the Paragraf company from receiving about 4 million dollars of investments at the beginning of last year. It should be noted that most of the funding was provided by the University of Cambridge. This practice for the school – a common thing. Many projects of university members were funded that way.

Graphene helped a group of scientists from China create all-weather solar panels. Innovation is a device that can receive energy from sunlight and rain drops with equal efficiency. It is a graphene film that allows you to generate energy from falling drops. Photovoltaic modules of Chinese scientists have become a miracle of modern technology thanks to the Gretzel cell.

It’s too early to talk about mass production and production of all-weather solar panels. This technology is still undergoing a series of necessary studies and tests. Many skeptics say that with an increase in the number of electric cars, humanity will need to increase the power of “non-environmental” energy production. The use of graphene in the production of solar panels and electric vehicles can provide tangible assistance in solving this issue.