In Odessa, one of the premises at the “Promzvyazok” plant was allocate for the production of solar modules. Firm “Info-Svyaz” is engaged in collecting panels for about 1,5 years. The plant, located on the outskirts of Cosmonaut Komarov, currently has vacant rooms. The management of the plant decided to lease them. Previously, in the vacant now workshops were engaged in the manufacture of telecommunication accessories.

A graduated historian Tulyuyuk Roman founded firm «Info-Svyaz» in 2009. At the initial stage of its existence, the company manufactured fiber-optic switching cables (patch cords) that were use to provide Internet communications. Only in 2013 began the production of solar panels.

Chief Engineer of the company-producer Viktor Lazarenko notes that the market analysis took 3.5 years. In addition, about 50 kg of photo-electronic transducers were damage. According to Mr. Lazarenko, members of their team attended various exhibitions of this direction, in the role of potential buyers went to foreign industries. The first pilot party was solder with its own hands. For the creation of a soldering machine, a half-cetera of FEPs was broken.

Chief Engineer of the company-producer Viktor Lazarenko notes that the market analysis took 3.5 years. In addition, about 50 kg of photo-electronic transducers were damage. According to Mr. Lazarenko, members of their team attended various exhibitions of this direction, in the role of potential buyers went to foreign industries. The first pilot party was solder with its own hands. For the creation of a soldering machine, a half-cetera of FEPs was broken.

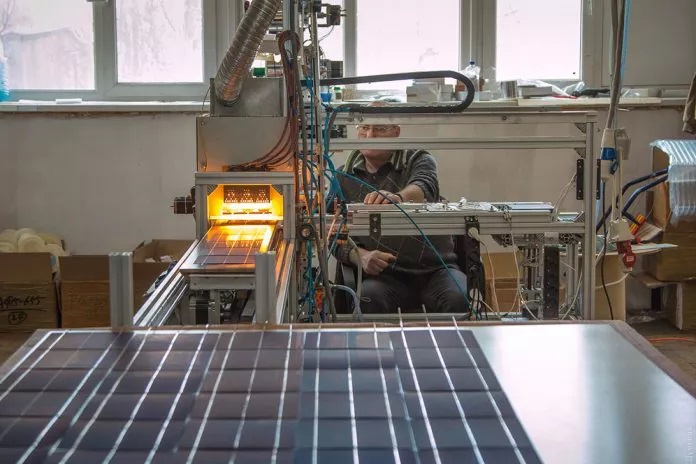

At present, four employees of the company are engaged in collecting solar panels. Animators from Odessa created a special program for the machine. This installation carries out a spike of copper-tin tires, which collect the produced electricity over the converters. One plate as a result includes three tires.

Photo-electronic transducers are thoroughly check to exclude the possibility of a defect. It should be note that the data components of the panel are very fragile and vulnerable, so employees carry them not bare hands, but using special vacuum suckers, and, 6 pieces at a time.

After transfer, the FEP is place on a tempered glass surface, covered with a layer of glue, and then with the help of dielectric cover with a special plate made of plastic or glass.

The resulting structure is place in a special oven and held there for ten minutes at 200 degrees.

Chief engineer said that the first two furnace complexes did not withstand the pressure of vacuum and simply developed. Vacuum is required to extract from future air remnants panels to prevent corrosive changes. Because of experimental work was spent about 5000 kg of metal. Now, due to this appeared two suitable stoves.

After baking, the plate is send to the stand, which includes halogen lamps. This is how the standard power values are checked.

Depending on the applied photo-electric elements, a solar panel measuring 1 × 1,6 m will have a power in the range of 260-315 watts (the figure of 275 watts is considered as the most optimal in the ratio of “cost-power”).

Today the company makes 25 solar modules in one working day.

Chief engineer noted that now the company is engaged in updating the production line, which will allow in the near future increasing the daily number of panels manufactured to one hundred.

Victor Lazarenko said that the company had set the retail price lower than that offered by Chinese manufacturers. However, the fight against wholesale purchases is unrealistic at this time. The company plans to organize its own production of FEPs in order to eliminate dependence on foreign suppliers.

Victor Lazarenko said that the company had set the retail price lower than that offered by Chinese manufacturers. However, the fight against wholesale purchases is unrealistic at this time. The company plans to organize its own production of FEPs in order to eliminate dependence on foreign suppliers.

According to the chief engineer, the legal power of the SES with the capacity of 30 kilowatts (for individuals) will have a payback period of 4-5 years. The price of one solar panel from the Odessa manufacturer is $ 130.

The company’s representatives estimated that the capacity of 10 kilowatts would be sufficient to meet the energy needs of the building (about 5 kilowatt-hours). In addition, with such power there will be an excess of energy that can be sold.

The novelty of the Odessa company is a plastic solar panel. Innovation has already been test on the first Odessa catamaran, which works thanks to solar panels. When there is cloudy weather on the street, the catamaran develops a speed of about 4 kilometers per hour due to “green” energy. In the future, plastic panels want to install on electric locks.