Solar panels, as well as any other system / mechanism, require a detail study and survey. Before acquiring expensive solar system for consuming and processing of alternative energy, it is worth carrying out careful diagnostics of the equipment. Maintenance and a research is necessary for high-quality and continuous operation of solar panels. Similar manipulations allow to reveal failure of solar modules at a stage of mounting or during direct operational process, and also to timely replace the damaged details. At least important there is a problem of fault recovery of electrical communications and connections that can significantly increase the general production properties of all power supplying system. An efficiency index – one more factor which influences operation of solar panels, and also the cost of “a green rate”.

Check method teplovizorny cameras

Quality of solar modules is a pacing factor which influences receiving, processing and saving solar energy. Duration of capacity of all system of power station in direct ratio depends on it. Payback of solar power plant and its ability to work smoothly are tightly connected to overall performance of the appropriate installations. To perform diagnostics of modules of solar batteries, it is possible to conduct their examination directly after the end of installation works.

If to use during production of solar batteries of a photo of links of low-quality composition, then origin of such problem as local overheating of sections is possible over time. It is possible to reveal similar malfunctions by means of thermal imagers, – such instrument allows to research most optimum and rationally system. All defects of a photo of links clearly and can accurately be considered on the thermal image of the appropriate cameras. Teplovizorny instruments allow to check installations directly during an operating time of solar panels. All possible and explicit problems can be revealed timely, using thermal imagers, even until blackout of system from working state. However, not each teplovizorny camera is suitable for diagnosing of solar batteries therefore it is necessary to treat attentively and responsibly this question.

Features teplovizornykh of cameras

Handheld teplovizorny cameras which have no the cooling detector are rather sensitive to “catching” of oscillations (8-14 microns). Considering that the protective area of solar installations isn’t transparent, the teplovizorny camera “sees” thermal radiations on the surfaces of glass and indirect distribution in links of modules (if to check a frontal surface). It means that temperature which was taken on the surface of the module will be different. It is necessary for high-quality and exact determination of temperature indices that sensitivity of the camera made ≤0.08 K. Advanced property of the teplovizorny device shall be at least 320*240 pixels. Existence of manual settlement of the range considerably will facilitate the task.

Methods of checks of solar batteries thermal imager

Diagnostics make 500 W/sq.m at the level of solar insolation. It provides the necessary thermal contrast and accurate thermal measurements. Sunny winter weather will be an ideal condition for conducting testing. The fitted viewing angle of a thermal imager concerning the area of solar modules is one more decisive factor truly. The exact line item of the instrument allows to avoid errors during diagnostics of a photo of links. “Green sector” with an angle at 5-60 ° – the recommended survey line item for thermal diagnostics. Such situation allows to scan a domestic situation of modules (it is desirable to carry out thermal photography of the lower part of the solar battery). This technique allows to reduce unnecessary solar and cloudy displays on glass. On back face contrast of temperature indices will be higher thanks to direct measurement of a surface of solar modules. Panels test in usual operating conditions during energetic loading. Varieties of a photo of links, measurements without loadings and during short circuits of modules are those factors which define optional data about working parameters of solar batteries.

Defects of solar batteries which can be defined during application of a thermal imager in diagnostics

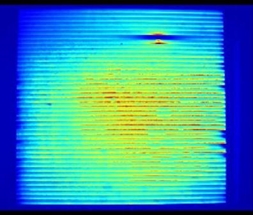

Parts of the solar battery which in case of a tangency hot, are clearly and precisely displayed on the monitor of the thermal camera. These parts are specified certain malfunctions of modules thanks to the form and layout of so-called “hot spots” on a surface of a photo of links. There is several other situation – solar to the battery more warmly in case of a tangency, than was before. It is an index of problems with connection of system. Heating up of separate photos of links or the whole bands of the battery testifies about defects in diode connections, about short circuits in the middle of system, and also about internal damages of a photo of crystals.

Possible defects:

1. “Band” defects of the reverse diodes;

2. Red spots testify to high power of links, and also show the damaged places;

3. Physical defects and mechanical damages of elements of installation can be revealed on existence of big “hot spot”.

Testing and diagnostics of solar panels with use the teplovizornykh of cameras gives an exact index of damage of separate elements and all system in general, and also reveals problems with electrical connections.

Important not only to perform internal inspection of installations, to track an instrument status during installation works, and also to perform periodic systematic inspections – it will give the chance to use solar panels most productively and throughout the long time.