MC-4 connectors are one contact electric sockets which usually use for connection of solar panels of a different look. MC-4 for the first time put connectors on the market “Multi-Contact”. Ordering of ranks of panels for more mild installation is the purpose MC-4, having pressed sockets, from the next panels of each other, manually. To disconnect, them express tools that they incidentally did not disconnect a cable are necessary. MC4 connectors and products, compatible to them, are the universal and more practical in the alternative solar power engineering for today. Equipment of almost all solar panels manufactured approximately since 2011 was made by means of MC-4 of connectors.

Common description of MC-4 of the connector

The MC-4 system consists of the plug and a nest. Forks and sockets are located in plastic envelopes so that is opposite to an opposite sex – a fork in a cylindrical cover which looks as the socket, but is remembered as “man”, and the socket in the square probe which looks as “man”, but electrically is “woman”. This socket has two plastic “fingers” which need to be pressed in the direction of the central clearance gage and to insert slightly into openings in the forefront of the socket. When two “fingers” shifted together slip down an opening and to a cut towards the socket where they appear above, there is their simultaneous fixing.

For the exact consolidation MC-4 producers demand use of a cable with the exact diameter. Usually double-insulated (isolation + a black envelope) and cables, resistant to an ultra-violet radiation (the majority of cables will work with time much worse if to use them in the open air without protection against a sunlight). Connection is made by means of the express blooming tool or by means of the soldering. At MC-4 sockets are alive at most 20 And yes 600 V, depending on the sizes of the conductor. The corresponding standards in Europe also allow to use and make the 1000 V conductors.

Prerequisites, creation basis

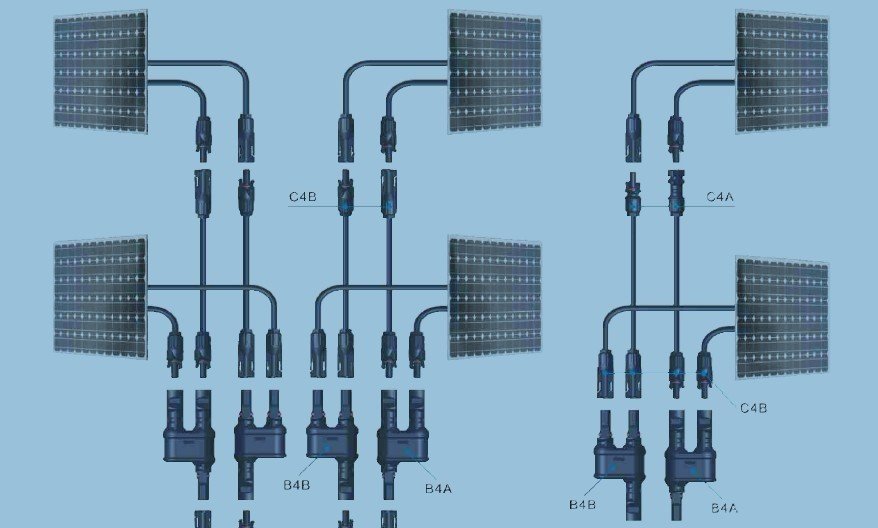

Small solar panels are used for charging of rechargeable batteries. Similar processes do not demand express connections while larger systems unite panels between themselves sequentially, creating express ranks. In the past it was reached due to opening of a small distributive box on the back panel and connection of the user by wires to screw plugs inside. However, “naked” terminals such are limited to 50 V or even less. Only the professional electrician can make connection. Besides, such connections constantly “face” such problems as water leak, electric corrosion and mechanical loads of wires. Since 2000th years, many companies showed products for the solution of these problems. In these systems the distributive box was sealed and two wires are permanently attached to it by means of a tension. Cables terminate in push-Fit in sockets which answer definition of “socket”, that is they can be bound among themselves. Double sockets, sockets “in” and the MC-3 socket which outwardly had an appearance of the pressurized stereos of sockets (jacks) became at that time very widespread.

In 2008 the American National Electric Code was updated. It gave the chance to demand from producers of solar panels of ” sockets the positive lock” so they can be connected manually now, but separation happens only to the help of tools. The European producer did not react to such specification of locks and since then disappeared in general. Two companies in the USA – “tyco Electronics” and “Multi-Contact” could understand the need for similar sockets and therefore achieved success in this sphere.

The “tyco Solarlok” company became the leader of the market of solar alternate energy on the end of the 2000th years, however, some factors developed in such a way that promoted its total disappearance. Among them there was a fact that the system has the 2nd sets of cables and wires which led to the considerable irritation in the area when an inventory of different producers cannot be connected together. Till 2011 MC-4 took the strong leader position that led to production of compatible products from the greatest suppliers of sockets. Among them there is “Amphenol Helios H4” and “SMK PV-03”.

Application, safety of use

Founders of Multilam MC technology claim that the constant pressure of a spring provides a reliable low support of contacts. However, they also note that it is very important not to connect and not to turn off contacts at loading, even in low-voltage systems (12-48 V). The electric arch during loading can melt and damage contact materials, as a result of a high support and an overheat. It often occurs because the parallel flow is directed towards an arch while removable current with larger readiness self-contained is usually used to die away in zero check point tension. Larger massifs of panels are usually connected in a series that consist of the line-ups and panels generating from 17 to 34 V in everyone from the common voltage up to 600 V in one row.

Shtekerny sockets, are manufactured not on MC technology, can be together with MC elements. Producers describe them as “MS-are compatible”. But manufacturers actually of MC connectors declare that such combinations of elements do not conform to requirements for a reliable electrical connection with long stability and safety. Therefore MC decline all responsibility if users connect improper elements. Interruption demands the express switch of a direct current which will allow to open a chain without defeat (120/230 B alternating currents, switches and switches are not suitable for increase in tension of a direct current).