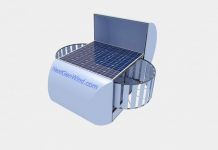

The polycrystalline solar panel is a kind of the national team of the silicon panel which absorbs solar energy for the subsequent its processing on thermal or electric. The main component is polycrystalline silicon which is received by a directional crystallization, and later divide it into equivalent parts. This type of panels is made of silicon polycrystals which in the device have full blue or blue shade, and also take the form of smooth squares.

Production

Process and the mechanism of manufacture of polycrystals is identical to monocrystals, however, there are particular differences. For production weed a link use silicon not of such high purity, than that is demanded by mono links. Thus, manufacture of this type of solar panels becomes cheaper several times. Polycrystals receive by cooling of silicon alloy, but passing an extract stage. Such manipulations allow to save on resources and energy consumption during production. After cooling alloy takes the form of ingots which divide into equal parts. The modern technologies allow to make polycrystals without creation of ingots, that is immediately from alloy. It is so created sheet weed silicon which has thickness of 100-300 microns.

Advantages and shortcomings

As well as any other energy source, polycrystalline solar panels have advantages and shortcomings which distinguish this look from others.

It is possible to refer the following criteria to advantages of polycrystalline solar panels:

- Cost of production and installation of elements. The cost of production and installation manages in the slight sum. It is bound to lack of need to use silicon of the highest purity, and also not the composite technological process of manufacture. On average with weed the cost of panels links 10% lower, than with mono links.

- High performance at low level of irradiating. Thanks to the nonuniform structure of a surface these panels are capable to absorb better than other types scattered light. Such characteristic allows the device to work smoothly during the interseasonal period, and also at a high cloudiness.

- High and uniform density of filling of a link. Pauly links have the legible and definite form, in a housing they densely adjoin to each other. Thanks to it all effective area of the solar panel is filled with photo cells. Such design allows polycrystalline solar panels to work not less efficiently, than monocrystal, despite identical dimensions of filling.

- Ecological factor, upkeep. Solar panels do not produce from harmful or toxic substances, the product of their activity is not dangerous therefore they do not damage a surrounding medium or health of the person at all. An upkeep of panels obliges only periodic dusting of an external design that does use of the device prime.

It is possible to refer the following criteria to shortcomings of polycrystalline solar panels:

- Efficiency loss. There is nothing eternal in this world, polycrystalline solar batteries not an exception. Despite the long serviceability, the type of solar panels over time given worsens the principal specifications. In comparison with monocrystal panels, polycrystalline work for about 10% worse. Researchers claim that in 25 years of continuous operation of panels with weed links they will lose 30% of effectiveness while mono links only 20%.

- Low efficiency. Panels that consist from weed a link really have much below than efficiency, in comparison with other types of solar panels. The index of an efficiency makes 12-18%. It is bound to what in internal filling weed a link sites with granular edges which cause decrease of overall performance of the panel are created.

- Decrease in overall performance at low air temperatures. Because of the specific structure weed links are not capable to work productively during the winter period, and also at low temperatures. On a counterbalance to this type of panels, mono links work several times more effectively.

Application

Polycrystalline solar panels are actively used at the various enterprises, productions and branches. Thanks to them it is possible to provide with the electric power and thermal resources of the place where traditional delivery is impossible or complicated. Most often with weed solar panels are applied by links:

- For power supply of the industrial and hotel and tourist facilities;

- For power supply of the remote objects of the oil and gas industry;

- For heat and power supply in agricultural objects;

- For power supply of complexes of a mobile and radio communication;

- For power supply of the equipment on a desalting and clarification of water;

- For lighting of streets, public places and objects of the recreational direction;

- Electro-and warm providing quotients and houses.

Polycrystalline solar panels can be installed anywhere, process of installation is not the composite or long. This device works independently and does not demand carrying out padding manipulations that does it rather practical. A design from weed a link does not demand any energy sources, except the sun that does it completely non-volatile from the central networks of delivery.

The alternative to traditional power supply exists – solar panels. In the conditions of global warming and at changes of climatic conditions such designs can become a potent energy source. Considering continuous increase in tariffs for power supply services, such method of providing will melt really urgent. And though such system for years pays off, the advantage and prospects of non-volatility are worth it.