Solid fuel boiler long burning differs from conventional solid-fuel boilers that has a larger interval between loads of fuel. Fuel here is peat briquettes, pellets, straw, reed, waste furniture production, as well as traditional firewood and coal. During combustion heat is given to the heat exchanger, which is difficult to find. The heat exchanger is a metal coil, it circulates the coolant (water). Then the coolant starts to move by the heating system. The duration of burning depends on what fuel is used and last an average of 2 – 8 hours. When the fuel is completely burned up, you need to clean up ash and again hold the tab fuel. In the boilers of previous generations this was done manually, the current models operate in automatic or semi-automatic mode. The fuel supply to them is made from special bins large enough volume. The fuel supply is performed by means of automation, which determines the boot time and the number of loaded fuel.

Solid fuel boiler long burning can be divided into 2 groups:

1. Pyrolysis boilers or gasifiers. In work on the chemical process pyrolysis. During pyrolysis, the combustion of fuel with high efficiency in the presence of a small quantity of oxygen. Are formed by this combustion: ash and combustible pyrolysis gas. The combustion process in boilers, pyrolysis occurs in two stages. The first stage is the smoldering solid fuel in the presence of a small quantity of oxygen. Such an environment can easily be done by installing a mechanical damper. During the second stage of combustion, volatile products of combustion are recycled. Adjusting the gas is done by means of thermostat. Like all devices, the boiler of this type has its pros and cons. The advantages of this boiler is that it is possible to burn large wood and, in contrast to conventional boilers, where the logs are completely burned, the combustion is complete. There remains only ash which is used as fertilizer. It is environmentally advantageous because there is no waste, and is economically advantageous, because it requires less cleaning of the ash pan, and the burning process is much longer. The system also has a fully automated process. Disadvantage is the high cost of аssembly, require forced pouting, and there is no way to bookmark fuel below normal and the fuel must be dry.

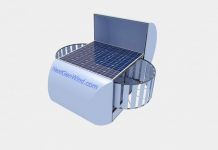

2. Boiler with upper combustion. Have a long burning fuel with one fuel loading. The minimum duration of combustion of one download – day, with a capacity of 5-6 kW. This is implemented due to the special design of the unit. The first distinctive feature is the lack of grate and ash pan. Instead, they used the pan, it prevents burning in this part. Heating part is made of cylindrical shape, and air is fed from the top. Therefore, the combustion of the top layer of fuel. Also the unit has a sliding air distributor that provides a uniform combustion throughout the entire time. As the heat exchanger in this type of boilers it is the case. The boilers are equipped with automatic traction control.

This two innovative devices that have different principle of work. Aggregates have a relatively large mass, for this reason is performed only in the outdoor installation version.