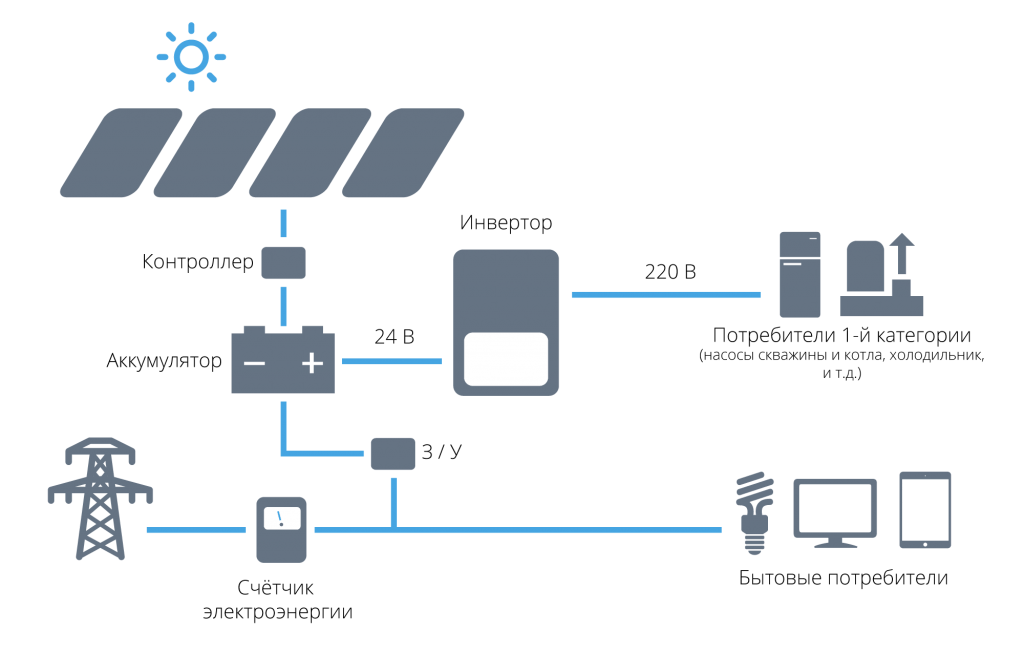

The basic equipment of a home-type solar power station looks like this:

– solar panels;

– inverter;

– controller;

– energy storage.

At first glance, such a system is simple and straightforward. It may even seem that the full-fledged work of the SES will begin after the elementary combination of all the components together. But this is far from the case. For the effective functioning of the system components must meet certain parameters and be combined with each other. If a non-professional is engaged in the assembly of components, then there is a high risk that SES will have very low productivity indicators and simply will not pay off. In addition, you should pay attention to the high probability of failure of one of the components of the system, which would entail additional expenses and the failure of the solar power plant.

In addition to installing solar panels and connecting them to the system, the specialist must calculate the required amount of energy. It should also take into account the peak load and the average daily energy consumption of households.

The main role in the calculations is played by the mode in which the SES will function. The following power supply modes exist:

– full;

– comfortable;

– basic;

– moderate;

– emergency.

Full power supply mode means getting energy exclusively from photovoltaic modules. The use of energy from the common network is not made. To transfer the household to the full energy supply regime, a solar power station should be installed, which will generate about 600 kilowatt-hours per month. In addition, such a system should operate at a power of 5 kilowatts. On average, a household’s daily energy consumption in such conditions will be 10–20 kilowatt-hours. The maximum load will have a value of 50 kilowatt-hours.

Comfortable power supply mode is characterized by the rejection of the use of some household appliances. The list of this equipment includes a convector, an electric stove, a water heater and other appliances that require large amounts of energy daily. A consumer may include irons, computers, a washing machine, etc. Provided the daily energy consumption does not exceed 8 kilowatts, the household energy consumption per month will be about 250 kilowatt-hours.

The basic mode of providing households with electricity noticeably changes the consumer’s lifestyle. The specificity of using this mode is to constantly monitor the amount of energy used. The user should always be guided when you can connect to the network of certain appliances, depending on the load. This mode involves the inclusion of a certain technique only in case of emergency. Energy consumption per day will be approximately 3-4 kWh.

With a moderate energy supply at home restrictions on the use of electric kettles, water heaters, underfloor heating, etc. are assumed. This approach does not change the life of the user too much, although it will still be necessary to make certain concessions for the sake of economy. It is also worth paying attention to the dependence on weather conditions in this mode. Indicators of the nominal power of such a power plant will be within 3-5 kilowatts.

The most limiting is the emergency power supply mode. The user will experience all the savings in everyday life. Autonomous operation of the system will be carried out only a few days. This mode is applicable in difficult cases when it is impossible to obtain electricity in another way. The use of most electrical appliances will become impossible, in winter even a refrigerator will become an inaccessible luxury. Energy consumption per day will be about 1.5 kilowatts.