The Francis Turbine was invented by the American James Francis in 1849. New technical solutions for water turbines have led to the fact that this type of turbine was installed on slopes up to 5 m. Francis turbine solutions are similar to Kaplan turbines with a difference in rotor and steering wheel designs. The flow parts of the Francis turbine are: the steering wheel, the rotor, the suction pipe, and the often encountered body of a special shape in the form of a boiler, funnel, or coil, the task of which is to supply water to the steering wheel (Fig. 1).

The rotor of the Francis turbine consists of two rims connected by blades. Depending on the slope and the power unit, the turbine blades are made in various ways. At altitudes up to 50 m and units of low and medium power, they are made of soft steel sheet under a press, and then connected to cast iron rings when casting or welded with steel rings.

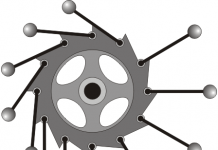

The blades, designed to work on large volumes and more powerful units, are made of cast steel with one or more castings (Fig. 3), and welding is used to connect these elements. The rotor blades rotate around the remote pins that connect the steering wheel cover to its base.

Another solution is a blade connected to the hinges, which rotates on bearings. One of the bearings is installed in the cover, and the other at the base of the steering wheel.

Fig. 1. Francis horizontal shaft with internal regulation; 1 – impeller, 2 – steering wheel cover, 3 – steering wheel support, 4 – adjusting ring, 5 – steering spatula, 6 – connector, 7 – bumper, 8 – turbine shaft, 9 – transverse-axial bearing, 10 – gland, 11 — control shaft, 12 — adjusting lever, 13 — outboard bearing, 14 — stuffing box, 15 — adjusting shaft bearing, 16 — double-lever lever, 17 — adjusting rod, 18 — curvature, 19 — suction pipe, 20 — pipe leakage, 21 – wall ring.

The components of the steering wheel are designed to operate the turbine blades and regulate the flow of water to the rotor. This regulation can be called external regulation, because the control system is outside the space filled with water, whereas if this system is located in a space filled with water, it is an internal regulation (turbines operating in low flow conditions).

Water flowing from the impeller may be directed to the drainage channel by means of a suction pipe with direct suction or curved. The suction pipe creates a negative pressure at the exit of the rotor and is designed to restore some of the kinetic energy of water leaving the impeller.

Francis turbines with vertical shafts (Fig. 2) are used mainly at low altitudes, and in the case of large leaks, turbines with horizontal shafts are used. On slopes of no more than 15 m for low and medium capacity Francis turbines, concrete chambers, open or closed, with slopes of 25 m in a concrete spiral, with slopes of about 100 m in a tin or cast iron chamber are usually constructed, while at even greater slopes spiral made of cast steel. For higher speeds, multi-rotor turbines are used.

Fig. 2. Francis Turbine with Vertical Shaft

The advantages of Francis turbines are the possibility of changing their design, which allows the most advantageous to choose a turbine for the construction of power plants, equipment for power plants and facilities in separate areas.

Fig. 3. Francis turbine rotor.

The disadvantages of the Francis turbines are the frequent occurrence of small leaks at the periphery of the rotor. To eliminate this problem, sealing rings for low flow turbines are used.